Creation of a Lightweight G2CS Copy (2017)

When this bike came into our lives it was already as a complete special of an unknown person’s creation. It had a heavily modified G2 lightweight frame fitted with a non AMC engine and a BSA/Triumph front brake. The bike came initially to me in an exchange with our section leader Roy and I used it in this form for a couple of years or so until I decided that it was not really what I wanted to keep. My (and Roy’s) friend Ken had helped me a lot with rebuilding the engine of another of my bikes and as I already had plans for the non AMC engine of this bike to be a spare for yet another of my bikes I gave the remaining rolling chassis of the special to Ken as thanks for his help. He in turn intended to return it to its original form with a standard G2/Model 14 engine but with minimal electrics and semi off road style.

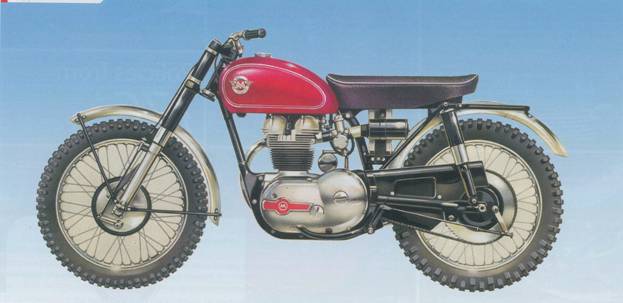

AMC promotional picture of the 250cc Matchless G2CS model

Although the intention was to produce a bike vaguely looking like the G2CS in the picture it was never intended to try and replicate the original in any way, especially as although they didn’t look a lot different from the road bikes the parts for these that were different were in the hen’s teeth category.

As we (well Ken really as I was mainly just observing and lending a hand when needed) were starting without any engine and a rolling chassis with a heavily modified frame (lightweights have a frame which consists of a pressed steel undertray made up of two pieces) and no engine Roy’s help was gained to search out new undertray components, gearbox mounting plates and parts with which to build up an engine and gearbox. Very soon boxes of bits arrived which had a set of undertray components from an undetermined model (there are actually three different types it seems) and most of the dismantled parts of an engine unit (although not all from the same engine) which had obviously suffered some serious abuse at some time and a complete gearbox unit which seemed to be seized. Not too promising a s a rebuild project but something for Ken to get started on. At least it would have been if Roy had not turned up first, saying that he had found a real G2CS set of crankcases so why not build up the bike as a proper G2CS replica. And having persuaded Ken, that’s where the real trouble started.

I don’t think that Roy, when he suggested

that, had any real idea of just how much extra work it would take to even

partly achieve his idea of a replica, or that Ken, who had no previous

experience of the AMC lightweight models realized it either when he agreed, but

he certainly understood at the end. The crankcases for the G2CS are cast so

they give an offset to the left when mounted in the frame,

this is to give clearance when a 4 inch rear tyre is

fitted instead of the normal 3.25 inch of the road bikes. This in itself

doesn’t sound so bad except when the fact that the swinging arm also needs to

be wider by the same amount and the gearbox support mountings to the frame also

have to be altered to take this into account and the undertray

pressings altered to suit. The G2CS swinging arm, was

in the usual “unobtainable”, or unaffordable category. “No matter”, says

The “re-made” swinging arm with its longer pivot pin

and extra bushes to take up clearances

Eventually though after a lot of effort,

trial and error and much heartache, all that was achieved, together with a

modified single sided front brake hub from an early heavyweight single to

replicate the look of the unit fitted to the real G2CS and the bike started to

take shape.

The gearbox turned out to be not a problem and after freeing off everything the gears all changed well enough and the gear teeth and dogs all seemed to be in quite good condition. However the same could not be said for the collection of mismatched and poor condition parts for the engine. The cylinder head was obviously from a late model CSR, because it had coil valve springs. But as for the rest it was anyones guess as to the age and model they came from. There were two crankshafts, both seized and both different, one of which we were told was from a G2CS. The parts book didn’t exactly help with this either, as it only showed one picture for all the models (including the 350s) and just gave the different part numbers for the different models against the one diagram. Eventually this was solved by ordering the only big end spares now available and rebuilding that shaft which they fitted. This was then trued up as best as could be obtained with such old and used parts, which was still within factory limits.

As no carburettor came with the bits a new Amal Monobloc, jetted appropriately, was bought and after overcoming a slight problem with engine breathing the engine started to come together. One big problem was the complete lack of any electrics amongst the parts and as Ken didn’t want to use any sort of battery system he decided to use an electronic system from Electrex World as he had used one of these successfully in the past on a BSA C15.

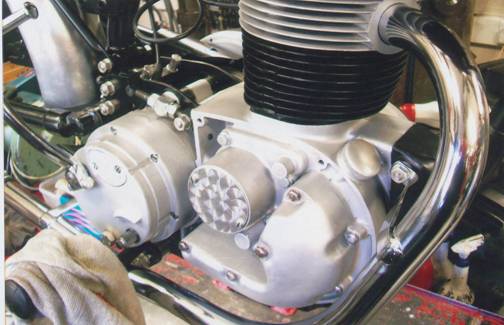

Old points housing now redundant and the gearbox

mountings with the re-made spacers in situ

The Electrex World unit was designed for the BSA C15/B40 type of unit and replaces the normal altenator unit, providing a good spark with electronic advance but no battery charging, which is fine for a bike that is not going to have lights fitted. There is one big difference between the BSA and AMC altenator fittings though. Whereas the stator on the BSA is fitted to the back of the primary chaincase and can therefore be easily set for air gap and timing, AMC, in their wisdom, decided to fit the stator within the outer primary chaincase, making it extremely difficult to set an air gap (especially with parts that didn’t start off from the factory together) and even more difficult to set the timing marks. However, after much experimentation it was deemed to be probably OK and we had a good spark at the plug.

With the head reconditioned the barrel didn’t look bad and was within tolerance so a set of rings was purchased from a supplier (not any that advertise within the club) and finally all was ready for the first start up. It wasn’t exactly a first kick start as we had yet to find the right settings of throttle, choke and air screw, but it had a decent compression and when it did start it sounded fine and oil was seen to be circulating OK. From the way the engine responded to the throttle it appeared that after all the checking that the new ignition system had been set in the right place after all. Elation was short lived though as it soon started smoking like a destroyer trying to evade attack. Initially the engine breathing came under suspicion but even with that sorted out it still smoked just as bad and when the barrel was lifted it was seen that the rings were not fitting properly at all and were barely touching the bore in places, so a rebore it was going to have to be and as unfortunately no new pistons could be obtained for the next size up it had to go up two sizes. The piston was obtained from the Club spares scheme, although it is not known exactly what model it was meant for or the compression ratio which it might produce when matched with the late CSR cylinder head.

With it all back together the compression was now very good indeed and quite a bit more than my own 350cc lightweight G5, but once the knack of kickstarting it with this new higher compression had been found it started readily enough and appropriate carburettor adjustments were made. There was now no smoke at all and the engine certainly had a healthy bark to it, even with a “gash” silencer tacked on to its open exhaust to reduce the anti social effects a bit. All the gears could be obtained and the clutch freed readily enough, although there was nowhere to actually try the bike out by riding it at all as it was not yet road legal.

As Ken no longer rides these days and the bike was not a style that appeals to me it was sold to someone who is an enthusiast for the AMC G2CS model and who fully understood what this bike actually was. He phoned Ken some while later to say that he had found it easier to start than any of his other versions and also that it was smoother running as well, which is perhaps as it should be being that most of the moving parts inside the engine were now new and had been very carefully put together by Ken. He also said that it had reached 54mph as a maximum speed (which, bearing in mind the very low gearing surprised me somewhat) and at which point Ken felt he had to remind him that it had not been “run-in” at all when he bought it. This bike had one further trick to play though. When the new owner came back from his initial maximum speed “thrash” he found that one of his trouser legs had been sprayed with oil. Now when Ken had first started this project I mentioned to him that when the lightweights had first been introduced AMC had a lot of trouble with porus cylinder barrel castings, indeed my own G5 model leaks a certain amount of oil through its cylinder barrel casting, although in my case it doesn’t really cause a problem and actually helps to stop the barrel from going rusty. But some, such as the one on this bike were very much worse, but how can you possibly know there is a problem until you can run the bike on the road. In this case it meant that the re-bore cost was completely wasted as the barrel was unuseable. Fortunately the new owner happened to have among his stock of parts a good barrel with the right bore to match the new piston, so all was made well again.

My own thoughts are that it would have been

much better to have built it up as a road going G2 model again and it would

have made a really nice road bike. It would certainly have been a lot quicker,

cheaper and easier to have done so, especially when the amount of information

produced on the G2CS model by AMC in written documentation, diagrams, manuals

or pictures is almost non existent, as are any spare parts that are

specifically for that model. However with

Return to East London and Essex Home Page