Burman B52 Gearbox help please

-

nomisimon

- Member

- Posts: 123

- Joined: Sat Sep 19, 2020 10:26 pm

- Location: Northumberland, England

- Contact:

Re: Burman B52 Gearbox help please

Hi Mick

I did wonder if that was the case, but the outer cover does not appear distorted at first glance. I need to investigate further but am currently slowly emptying my 'Matchless Repair Fund' into the accounts of various suppliers to get the parts I need to do a proper rebuild on the gearbox. Some of the parts 'will do' but I don't want to be inside again any time soon so will replace them.

Tomorrow is a CT scan in hospital but hopefully on Friday I'll pop the gearbox body in the oven to around 100C which should allow me to get the bearing and stuck oil seal housing out. The gearbox body was easy to remove from the bike of course, once it was stripped.

Following that, I need to clean the shafts and gears...then check to see there is no runout on the mainshaft and take a better look at the selector forks.

Let me know if you think the oven idea is not a good one and I'd be interested to know if there's a recommended way of straightening the selector fork(s) and in the worst case, the mainshaft.

Best wishes

Simon

I did wonder if that was the case, but the outer cover does not appear distorted at first glance. I need to investigate further but am currently slowly emptying my 'Matchless Repair Fund' into the accounts of various suppliers to get the parts I need to do a proper rebuild on the gearbox. Some of the parts 'will do' but I don't want to be inside again any time soon so will replace them.

Tomorrow is a CT scan in hospital but hopefully on Friday I'll pop the gearbox body in the oven to around 100C which should allow me to get the bearing and stuck oil seal housing out. The gearbox body was easy to remove from the bike of course, once it was stripped.

Following that, I need to clean the shafts and gears...then check to see there is no runout on the mainshaft and take a better look at the selector forks.

Let me know if you think the oven idea is not a good one and I'd be interested to know if there's a recommended way of straightening the selector fork(s) and in the worst case, the mainshaft.

Best wishes

Simon

Thank God for Southby

-

Mick D

- Posts: 2884

- Joined: Mon Mar 24, 2014 5:44 pm

- Location: Aberdeenshire

Re: Burman B52 Gearbox help please

Hi Simon

The oven is fine but any oil or cleaning fluids will evaporate/ smell and may affect household harmony Heating outside with a camping stove, plumbers gas torch or even a small bonfire may be a less fractious option.

Heating outside with a camping stove, plumbers gas torch or even a small bonfire may be a less fractious option.

I'd suggest you get the oil seal and holder out before you remove the bearing, this will ensure the oil seal carrier cannot catch on the circlip groove and interfere with the bearing removal. You should be able to flip the oil seal holder out with a couple of screw drivers, give it a good soaking in solvent, (petrol / paraffin), and work around it gently levering.

There's no reason why the selector forks or any of the shafts cannot be straightened, for the shafts I'd use a press and measure the run out between centres or vee blocks with a dial gauge. Once the selector shaft is true the fork can be 'clocked' perpendicular to it.

Regards Mick

The oven is fine but any oil or cleaning fluids will evaporate/ smell and may affect household harmony

I'd suggest you get the oil seal and holder out before you remove the bearing, this will ensure the oil seal carrier cannot catch on the circlip groove and interfere with the bearing removal. You should be able to flip the oil seal holder out with a couple of screw drivers, give it a good soaking in solvent, (petrol / paraffin), and work around it gently levering.

There's no reason why the selector forks or any of the shafts cannot be straightened, for the shafts I'd use a press and measure the run out between centres or vee blocks with a dial gauge. Once the selector shaft is true the fork can be 'clocked' perpendicular to it.

Regards Mick

- Pharisee

- Member

- Posts: 1127

- Joined: Tue Mar 15, 2016 8:51 pm

- Location: Lincolnshire UK

- Contact:

Re: Burman B52 Gearbox help please

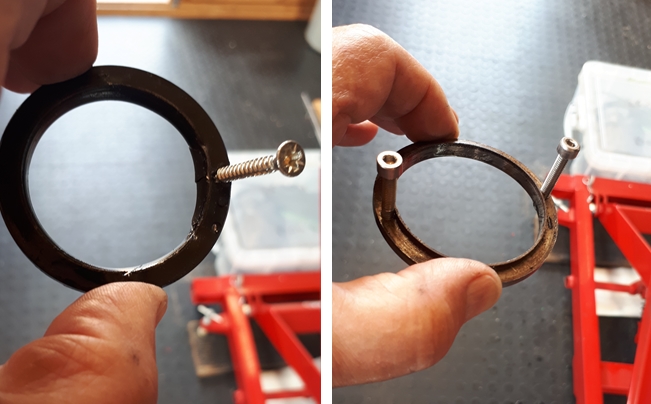

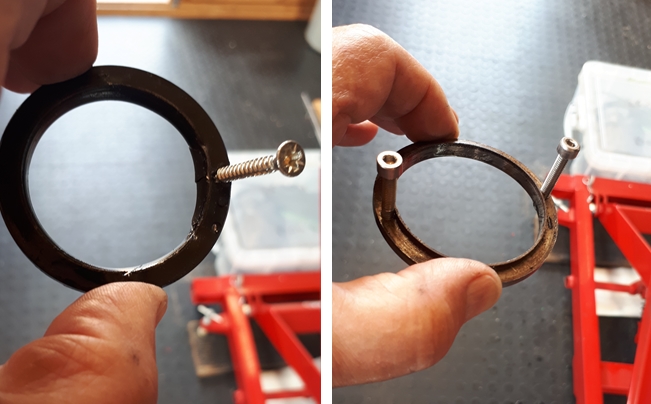

A self tapping screw into the oil seal and a sharp tug with a pair of pliers will usually get the oil seal out and sometimes the steel ring will come with it. If it doesn't, I've drilled into the ring on opposite sides (and finished off with a flat bottomed drill) and then tapped the holes M4. Screw two M4 screws in and when they bottom out on the bearing outer ring, they push the steel ring out. Only good if you're going to replace them, of course.

I'm from the Fens.... Gimme six.

- 1608

- Member

- Posts: 2495

- Joined: Mon Oct 05, 2009 1:00 am

- Location: ESSEX UK

Re: Burman B52 Gearbox help please

I have found that placing alloy casings in a bowl of boiling water is as effect as oven use on several occasions, no risk of upsetting swmbo . Worth a try first

-

nomisimon

- Member

- Posts: 123

- Joined: Sat Sep 19, 2020 10:26 pm

- Location: Northumberland, England

- Contact:

Re: Burman B52 Gearbox help please

Hi Pharisee - thanks, the oil seal and housing were much easier to remove than I expected. I was able to lever each out, in turn, using large screwdrivers levering against the oil seal housing and old bearing respectively. Just the bearing now.

Hi 1608 - thanks...I don't have a swmbo but I'll give the boiling water method a try first. The bearing, albeit without oil or grease in it, sounds as rough as a badger's a**e.

I'm still hoping for some advice on straightening a slightly bent selector fork. Here's a picture of the fork showing the bend.

[img][/img]

Hi 1608 - thanks...I don't have a swmbo but I'll give the boiling water method a try first. The bearing, albeit without oil or grease in it, sounds as rough as a badger's a**e.

I'm still hoping for some advice on straightening a slightly bent selector fork. Here's a picture of the fork showing the bend.

[img][/img]

You do not have the required permissions to view the files attached to this post.

Thank God for Southby

-

Mick D

- Posts: 2884

- Joined: Mon Mar 24, 2014 5:44 pm

- Location: Aberdeenshire

Re: Burman B52 Gearbox help please

Hi

It's difficult to establish the extent of the distortion from the photo, but if it's confined to the selector fork arms:

The selector fork will be made from cast steel and as such can be bent cold, if you're confident in your abilities, grip it in the protected jaws of a vice and ease it back into alignment, you will be able to do this by hand. Check the fork bears squarely on the sides of the groove in the second gear after straightening.

Regards Mick

It's difficult to establish the extent of the distortion from the photo, but if it's confined to the selector fork arms:

The selector fork will be made from cast steel and as such can be bent cold, if you're confident in your abilities, grip it in the protected jaws of a vice and ease it back into alignment, you will be able to do this by hand. Check the fork bears squarely on the sides of the groove in the second gear after straightening.

Regards Mick

-

nomisimon

- Member

- Posts: 123

- Joined: Sat Sep 19, 2020 10:26 pm

- Location: Northumberland, England

- Contact:

Re: Burman B52 Gearbox help please

Hi Mick D

Thanks...I wasn't sure whether it was safe to do or not.

Just in case, there was a chap selling a pair of lightly worn forks on eBay; they are the later type where the forks are part of the shaft. They are supposed to fit the B52/GB box.

I couldn't find a single selector fork for sale. At least I will have spares, and will use the newer shafts once checked.

The main bearing came out after using the 'boiling water on the gearbox' method; a few taps and out it came. I'm going to clean it all up, replace the core plug that has been missing from the end of the layshaft for decades by the look of it and check the mainshaft for runout.

and check the mainshaft for runout.

Then reassemble carefully.

It never ceases to amaze me how sparse a £200 bag of parts looks

Thanks again sir.

Simon

Thanks...I wasn't sure whether it was safe to do or not.

Just in case, there was a chap selling a pair of lightly worn forks on eBay; they are the later type where the forks are part of the shaft. They are supposed to fit the B52/GB box.

I couldn't find a single selector fork for sale. At least I will have spares, and will use the newer shafts once checked.

The main bearing came out after using the 'boiling water on the gearbox' method; a few taps and out it came. I'm going to clean it all up, replace the core plug that has been missing from the end of the layshaft for decades by the look of it

Then reassemble carefully.

It never ceases to amaze me how sparse a £200 bag of parts looks

Thanks again sir.

Simon

Thank God for Southby

-

Mick D

- Posts: 2884

- Joined: Mon Mar 24, 2014 5:44 pm

- Location: Aberdeenshire

Re: Burman B52 Gearbox help please

Best to avoid Triumph and Norton thennomisimon wrote:It never ceases to amaze me how sparse a £200 bag of parts looks

-

nomisimon

- Member

- Posts: 123

- Joined: Sat Sep 19, 2020 10:26 pm

- Location: Northumberland, England

- Contact:

-

nomisimon

- Member

- Posts: 123

- Joined: Sat Sep 19, 2020 10:26 pm

- Location: Northumberland, England

- Contact:

Re: Burman B52 Gearbox help please

I am now ready to fit the new bearing, oil seal housing and oil seal.

I'd like to double check the assembly procedure:

- the main shell will be heated to about 90 degrees in the oven, the bearing is in the fridge.

- I don't think it matters which way the bearing is installed...is that correct?

- the oil seal housing comes next with the flange protruding out over, as per the old one.

- the new oil seal is next...do I want the flat side of the new seal pointing out over or the part with the hollow in it where you can see the spring?

- should I fit the seal to the housing before installation, and from which side?

Thanks

Simon

I'd like to double check the assembly procedure:

- the main shell will be heated to about 90 degrees in the oven, the bearing is in the fridge.

- I don't think it matters which way the bearing is installed...is that correct?

- the oil seal housing comes next with the flange protruding out over, as per the old one.

- the new oil seal is next...do I want the flat side of the new seal pointing out over or the part with the hollow in it where you can see the spring?

- should I fit the seal to the housing before installation, and from which side?

Thanks

Simon

Thank God for Southby